- Home

- Products

- Asphalt/Bitumen Melter

- ZYDST Series Asphalt Barrel Melter

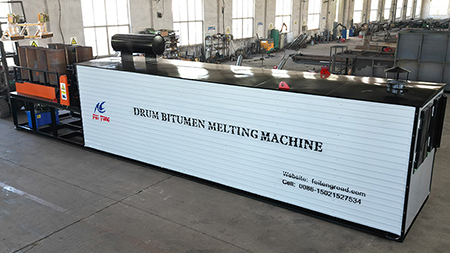

ZYDST Series Asphalt Barrel Melter, Bitumen Drum Decanter

ZYDST series asphalt barrel melter is designed to efficiently melt drummed bitumen using high-temperature thermal oil as the carrier and a diesel burner as the heat source. This bitumen melting equipment employs heating coils and hot air to achieve rapid and effective heating, decanting, and melting of the bitumen. The unique feature of this asphalt decanter is that it eliminates the need for an external thermal oil boiler by integrating the thermal oil boiler directly into the decanting equipment. This integration ensures optimal heating performance and offers several advantages, including high thermal utilization efficiency, fast drum decanting speed, high level of automation, and reduced pollution.

| Model | ZDLT-5 | ZDLT-10 | ZDLT-15 | ZYDST-5 | ZYDST-10 | ZYDST-15 | ||||||

| Production capacity (t/h) | 4-6 | 8-10 | 10-15 | 4-6 | 8-10 | 10-15 | ||||||

| Bitumen tank capacity m³) | 9 | 14 | 19 | 9 | 14 | 19 | ||||||

| Drum quantity | Dia.:580mm; 18 | Dia.:500mm; 22 | Dia.:580mm; 28 | Dia.:500mm; 32 | Dia.:580mm; 42 | Dia.:500mm; 48 | Dia.:580mm; 18 | Dia.:500mm; 22 | Dia.:580mm; 28 | Dia.:500mm; 32 | Dia.:580mm; 42 | Dia.:500mm; 48 |

| Number of drum rails | 2 | 2 | 3 | 2 | 2 | 3 | ||||||

| Outer size(length*width*height) (m) | 9.45×2.2×2.55 | 9.25×2.2×2.55 | 12×2.2×2.55 | 12×3.1×2.55 | 9.45×2.2×2.55 | 9.25×2.2×2.55 | 12×2.2×2.55 | 12×3.1×2.55 | ||||

| Total power(kW) | 10.5 | 13 | 15 | 15.2 | 17.7 | 20.1 | ||||||

| Diesel oil burner capacity (Kcal/hr) | - | - | - | 400,000 | 470,000 | 720,000 | ||||||

| Thermal oil heater capacity (Kcal/hr) | 400,000 | 600,000 | 800,000 | - | - | - | ||||||

The asphalt barrel melter mainly consists of a drum decanter, diesel burner, thermal oil circulation pump, combustion chamber and flue, heating coil, hydraulic automatic pusher, automatic drum tipping device, asphalt output pump, electrical control system, and other components.

This bitumen drum melter adopts self-closing doors, the asphalt drum can be lifted by a forklift or other machinery and placed on the entrance guide rail, and then pushed forward with simple and effortless operation.

- Fast drum decanting speed: the internal heating coil has a large heat dissipation area, which heats up quickly and has high production efficiency. The heating coil system adopts independent control technology for each zone, which can freely adjust the heat distribution between the drum decanting chamber and the melting pool to synchronize the drum decanting speed with the melting speed. It also effectively utilizes the waste heat of the high-temperature air from the diesel burner for heating, thus saving energy. The built-in heating furnace makes heat transfer more direct and reduces heat loss. The thick and high-quality rockwool insulation ensures excellent thermal insulation performance.

- Complete bitumen removal: The upper part of the bitumen decanting machine has a high heat output, and each drum is directly heated by the thermal oil coil, allowing the bitumen to be completely and rapidly removed without any residue sticking to the drum.

- Automatic slag removal: the asphalt pipeline system is equipped with a filter device that can automatically remove slag from the barrel through the filter screen.

- Convenient and environmentally friendly: there is an asphalt receiving tray with heating capacity under the automatic drum tipping device, which can collect the dripping asphalt and heat it, avoiding site pollution and asphalt waste.

- Highly flexible: the bitumen decanter can be customized according to various sizes and specifications of asphalt drums. You can rely on its flexibility and adaptability to meet different requirements.

- High degree of automation: It’s highly automated with automatic recognition, tipping, pushing, door closing, and resetting functions, significantly reducing labor costs.

- Easy transportation and installation: this asphalt melting equipment is easy to move and assemble due to its modular design.

- Patented technology: The asphalt melting equipment features the latest patented technology of an integrated design and automatic drum tipping and pushing system. The integrated design seamlessly combines the thermal oil boiler with the drum decanting equipment, resulting in reduced transportation costs, space requirements, installation, and maintenance needs. Moreover, the built-in heating combustion chamber design enhances heat transfer efficiency and minimizes heat loss. The automatic tipping and pushing technology significantly reduce labor costs while boosting efficiency.

Add.: Economic Development Zone of Wucheng County, Dezhou City, Shandong Province

Add.: Economic Development Zone of Wucheng County, Dezhou City, Shandong Province